FINDLAY, Ohio — A local company that usually supplies the automotive industry is now able to help medical professionals stay safe.

GVS Filtration in Findlay usually produces automotive air filters. But with its current automotive sales down 50%, the plant's 200 employees were in need of new business.

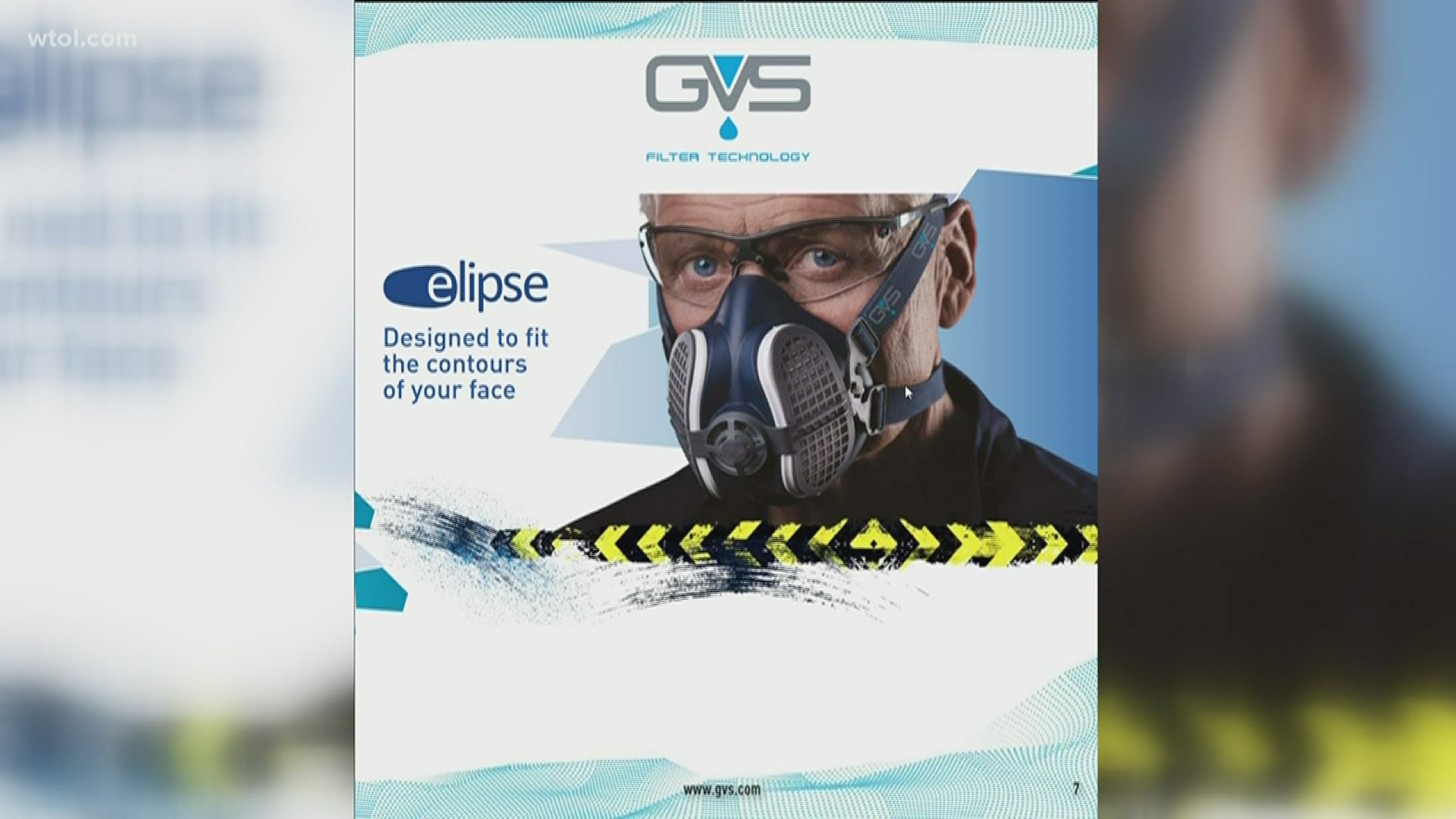

In response to COVID-19, the plant's parent company decided to install two new lines at GVS Filtration to produce a medical grade filter mask, and a respirator with replaceable air filters.

Over the last three weeks, GVS engineers have been working tirelessly to get these new lines up and running, a task that normally would have taken three to five months.

"It was an all hands on deck effort of divvying out different sections of the process since it's essentially two different lines and two different manufacturing processes," GVS Filtration director of continuous improvement and quality Chris Schoonover said.

GVS Filtration leaders plans on keeping these two new mask and respirator lines going, even after the coronavirus pandemic.

So, in the event that the automotive sales come back to full capacity, the GVS Findlay plant will eventually need to take on 60-65 new employees as well.

"You know, automotive as everybody knows, goes up and down and is kind of a volatile at times. This here gives us a more diverse operation with other things that we can work from now ," GVS Filtration operations manager Brad Butler said.

The plan is to begin running the first stages of the equipment Friday on the disposable masks and filter cartridges, with production of the half mask starting up in a few weeks.